Interlacing Jets for BCF spinning process

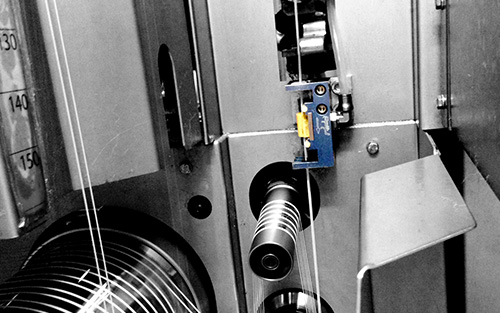

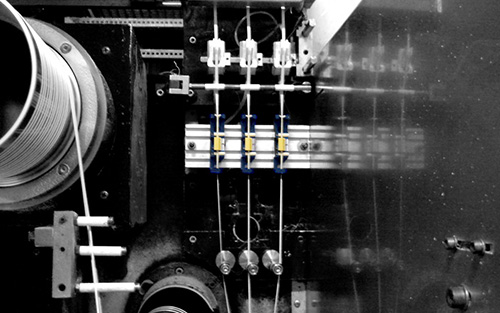

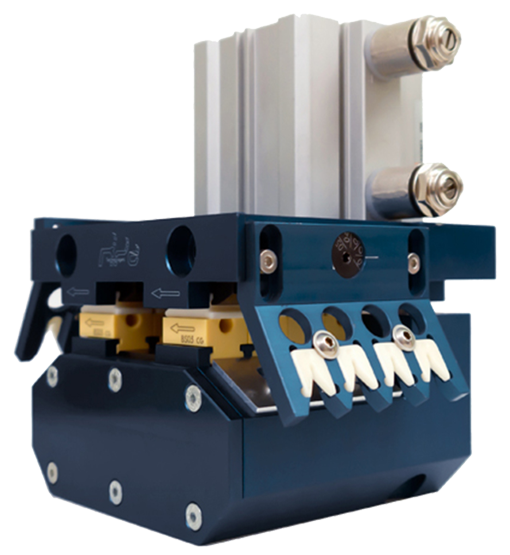

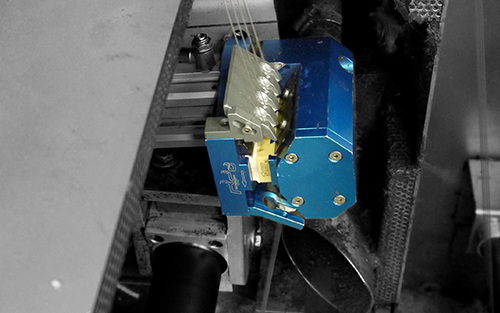

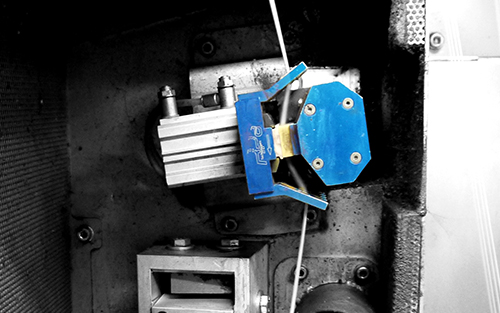

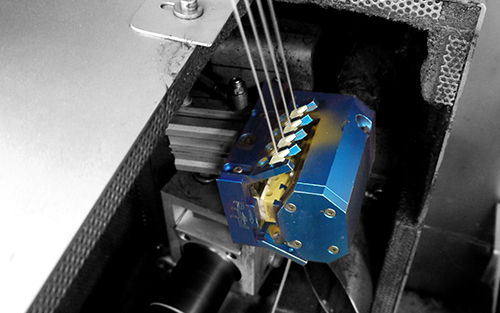

BCF interlacing jets

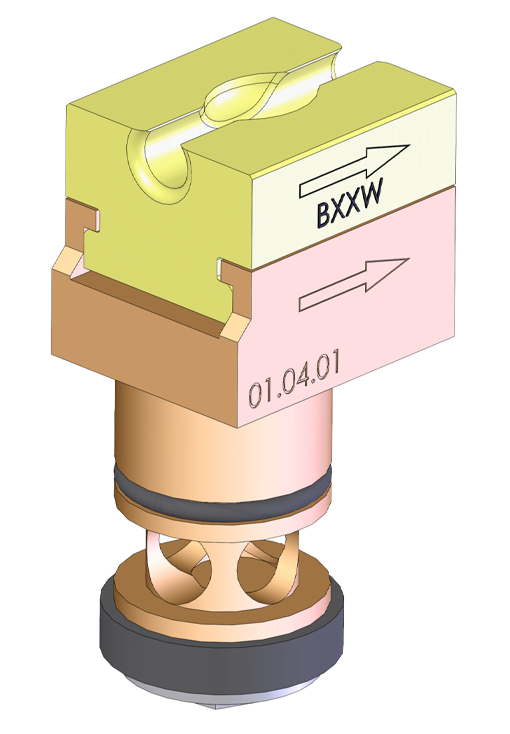

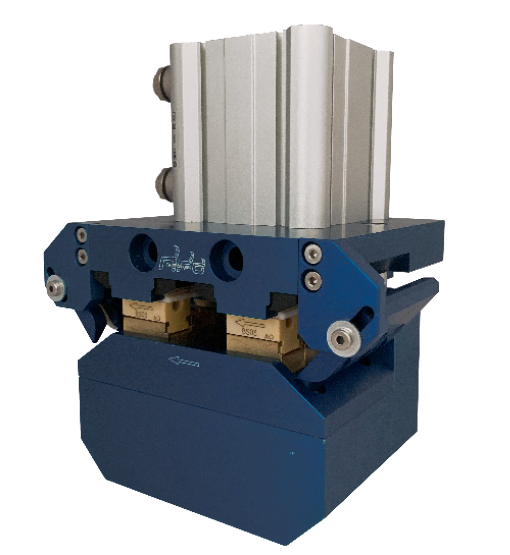

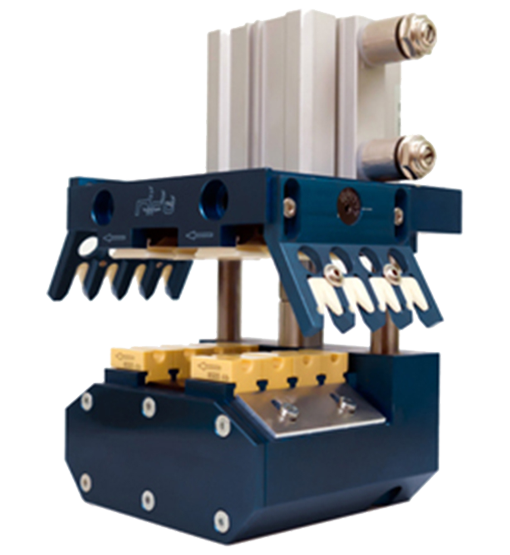

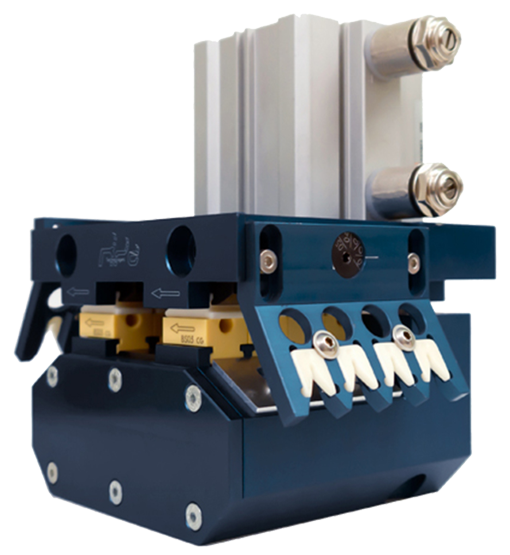

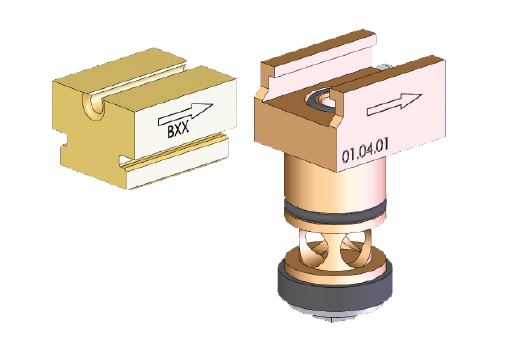

The designs are changeable to satisfy customer requirements according to yarn path, machine adaptation and air supply. The jets are available in single or tandem version, with or without integrated air stop.

2-thread single BCF jet

3-thread tandem BCF jet

4-thread tandem BCF jet, open

4-thread tandem BCF jet, closed

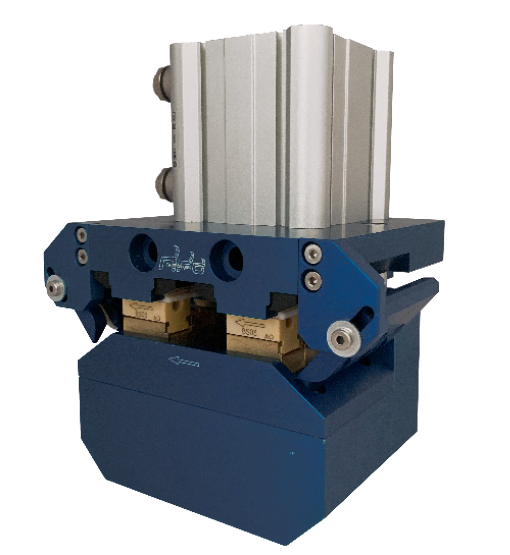

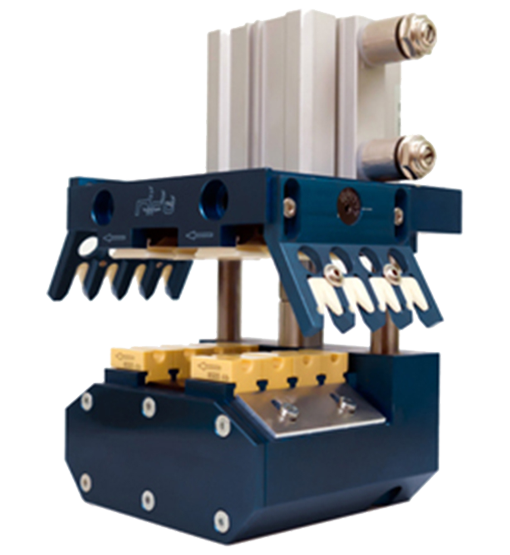

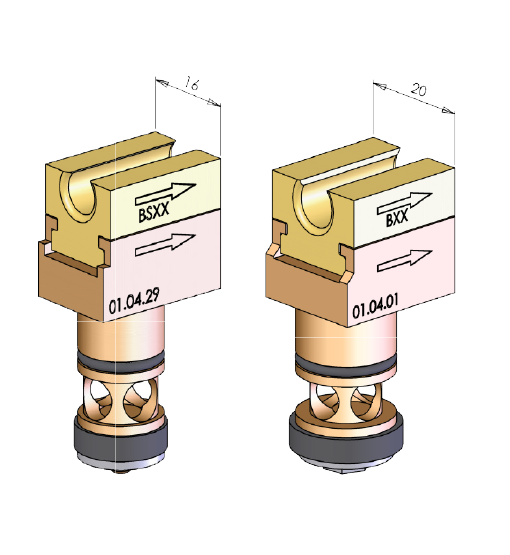

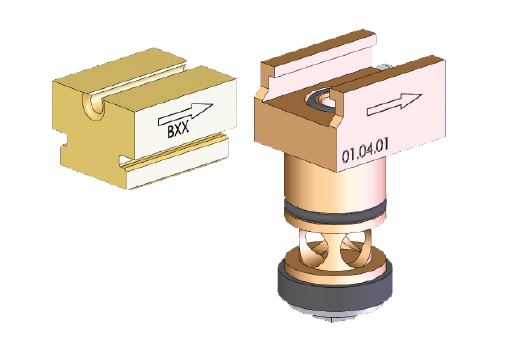

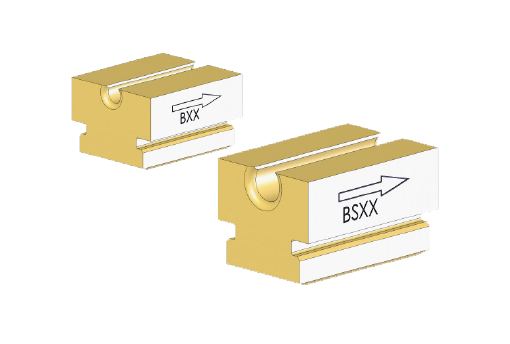

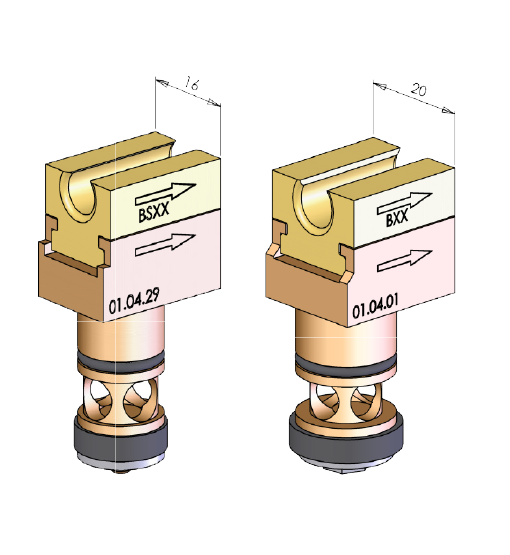

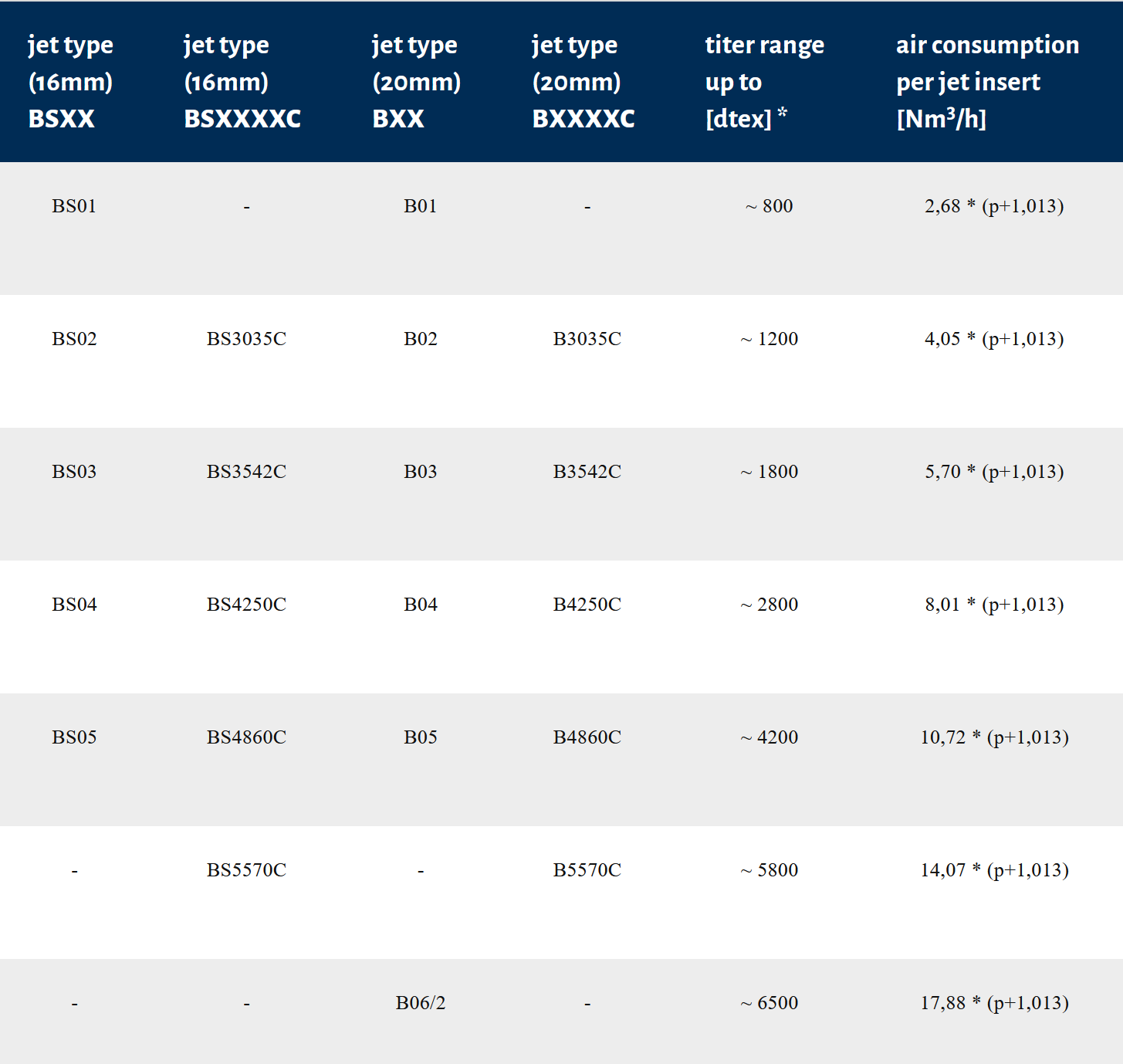

BCF jet inserts

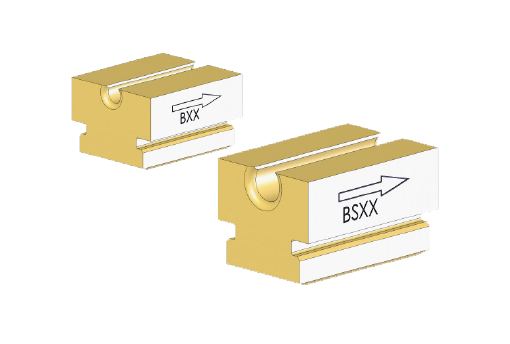

All the jet inserts are available in 20mm (e.g. BXX) as well as 16mm (e.g. BSXX) yarn end separation. Customized solutions with different yarn end separations according to special requirements are possible any time.

jet type BSXX | jet type BSXXXXC | jet type BXX | jet type BXXXXC | titer range | air consumption |

|---|---|---|---|---|---|

BS01 | - | B01 | - | ~ 800 | 2,68 * (p+1,013) |

BS02 | BS3035C | B02 | B3035C | ~ 1200 | 4,05 * (p+1,013) |

BS03 | BS3542C | B03 | B3542C | ~ 1800 | 5,70 * (p+1,013) |

BS04 | BS4250C | B04 | B4250C | ~ 2800 | 8,01 * (p+1,013) |

BS05 | BS4860C | B05 | B4860C | ~ 4200 | 10,72 * (p+1,013) |

- | BS5570C | - | B5570C | ~ 5800 | 14,07 * (p+1,013) |

- | - | B06/2 | - | ~ 6500 | 17,88 * (p+1,013) |

Most important for the right choice of insert size is the specific required interlace performance.

IN.B(S)XX

B(S)XX

B(S)XXXXC

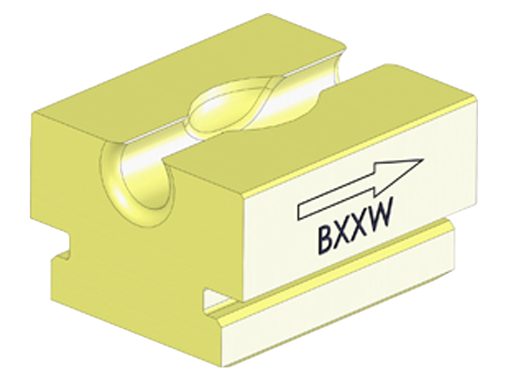

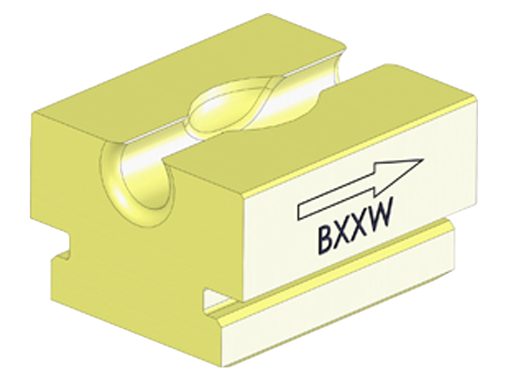

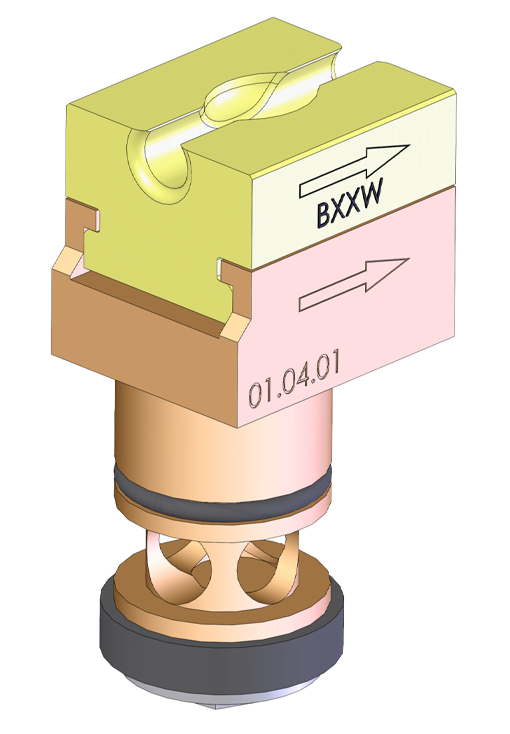

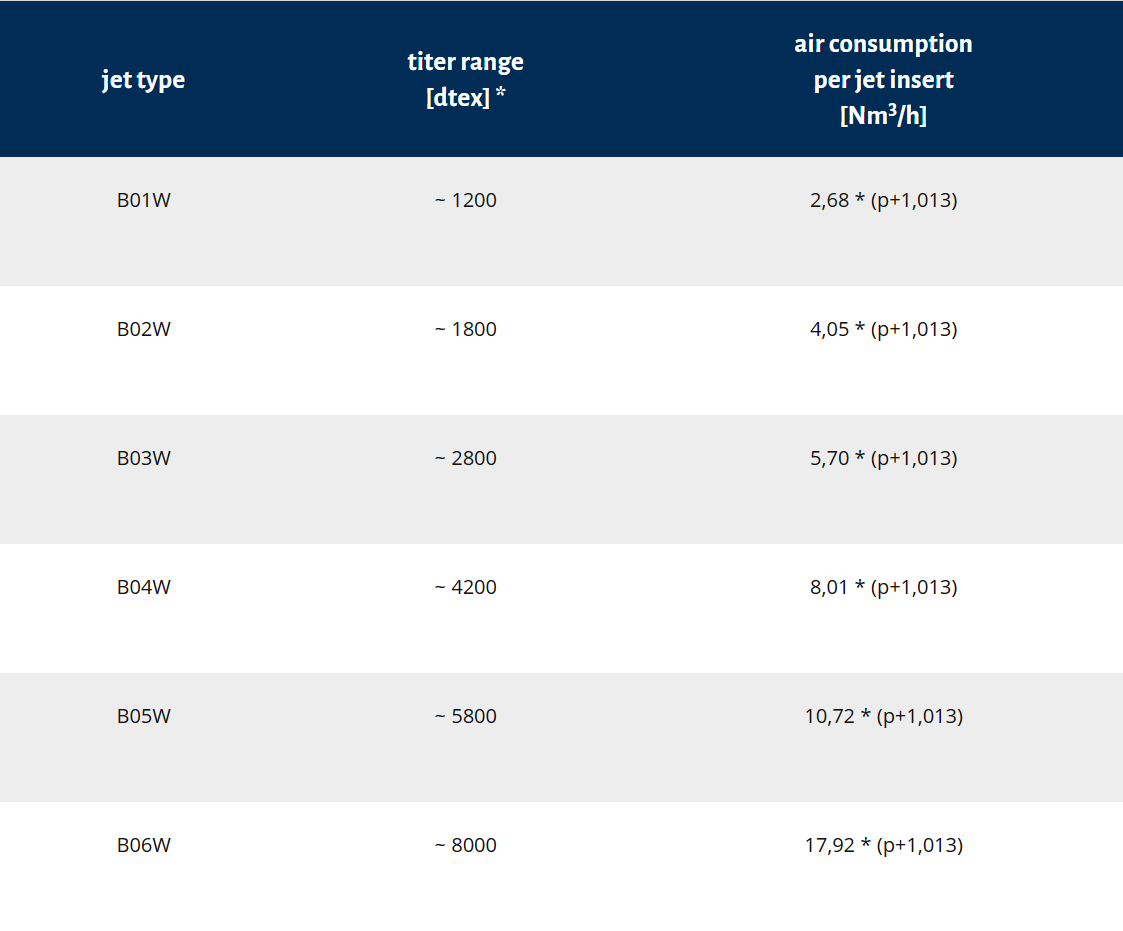

BCF jet inserts W-types

The yarn channel geometry of the W-types has a vortex chamber that enables larger titer ranges compared to standard channels. This means that in certain applications the required interlacing qualities can also be achieved with significantly lower air consumption.

This leads to an average saving in air consumption of 20% and significantly relieves the energy balance.

jet type | titer range

[dtex] * | air consumption

per jet insert

[Nm3/h] |

|---|---|---|

B01W | ~ 1200 | 2,68 * (p+1,013) |

B02W | ~ 1800 | 4,05 * (p+1,013) |

B03W | ~ 2800 | 5,70 * (p+1,013) |

B04W | ~ 4200 | 8,01 * (p+1,013) |

B05W | ~ 5800 | 10,72 * (p+1,013) |

B06W | ~ 8000 | 17,92 * (p+1,013) |

Most important for the right choice of insert size is the specific required interlace performance.

BXXW

IN.BXXW

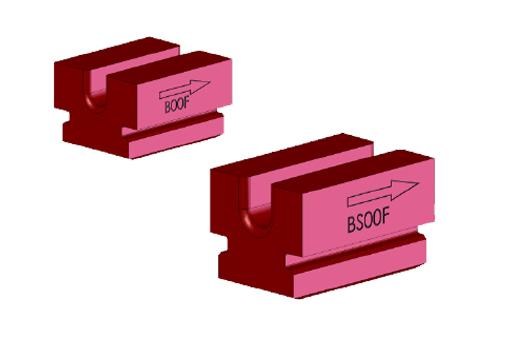

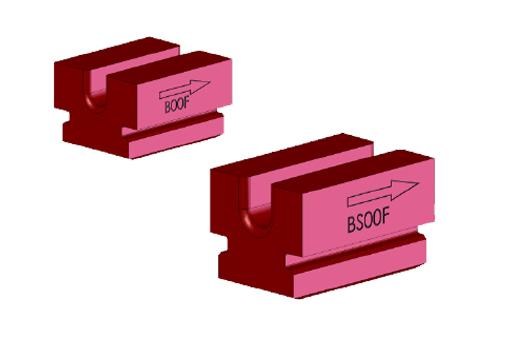

Blind Inserts

B(S)00F

B(S)00

BCF interlacing jets

The designs are changeable to satisfy customer requirements according to yarn path, machine adaptation and air supply. The jets are available in single or tandem version, with or without integrated air stop.

2-thread single BCF jet

3-thread tandem BCF jet

4-thread tandem BCF jet, open

4-thread tandem BCF jet, closed

BCF jet inserts

All the jet inserts are available in 20mm (e.g. BXX) as well as 16mm (e.g. BSXX) yarn end separation. Customized solutions with different yarn end separations according to special requirements are possible any time.

Most important for the right choice of insert size is the specific required interlace performance.

IN.B(S)XX

B(S)XX

B(S)XXXXC

BCF jet inserts W-types

The yarn channel geometry of the W-types has a vortex chamber that enables larger titer ranges compared to standard channels. This means that in certain applications the required interlacing qualities can also be achieved with significantly lower air consumption.

This leads to an average saving in air consumption of 20% and significantly relieves the energy balance.

BXXW

IN.BXXW

Most important for the right choice of insert size is the specific required interlace performance.

Blind Inserts

B(S)00F

B(S)00

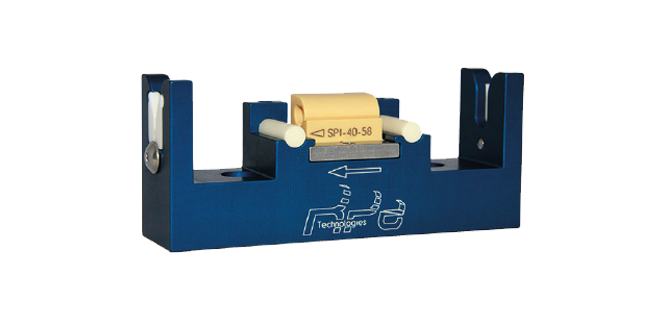

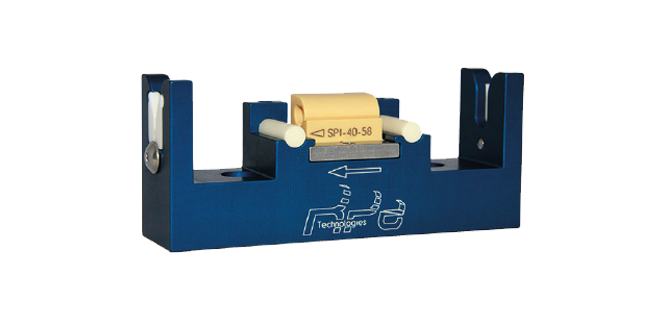

BCF pre-interlacing and migration jets

RPE offers two types of SPI interlacing jets (A- and B-Version) with different design to guarantee optimal results regarding the specific requirements of individual assembly situations and process flows. In this context our customers are advised by experts that have long experience regarding the choice of SPI versions.

The design of the SPI jet enables also multi thread jets for all conceivable number of thread lines and yarn end separations.

jet type | titer range | air consumption |

|---|---|---|

SPI-20-29 | 200 – 400 | 1,86 * (p+1) |

SPI-23-33 | 300 – 900 | 2,46 * (p+1) |

SPI-30-42 | 500 – 1200 | 4,19 * (p+1) |

SPI-35-50 | 700 – 1800 | 5,70 * (p+1) |

SPI-40-58 | 1000 – 3200 | 7,44 * (p+1) |

Most important for the right choice of insert size is the specific required interlace performance.

SPI jet, A-type

SPI jet, B-type

BCF pre-interlacing and migration jets

SPI jet, A-type

SPI jet, B-type

RPE offers two types of SPI interlacing jets (A- and B-Version) with different design to guarantee optimal results regarding the specific requirements of individual assembly situations and process flows. In this context our customers are advised by experts that have long experience regarding the choice of SPI versions.

The design of the SPI jet enables also multi thread jets for all conceivable number of thread lines and yarn end separations.

Most important for the right choice of insert size is the specific required interlace performance.