Interlacing Jets for IDY spinning process

The industrial yarn draw spinning process is probably the most challenging fibre production amongst flat filament yarn manufacturing. High tenacities and extreme good stabilities are required through a wide range of yarn counts.

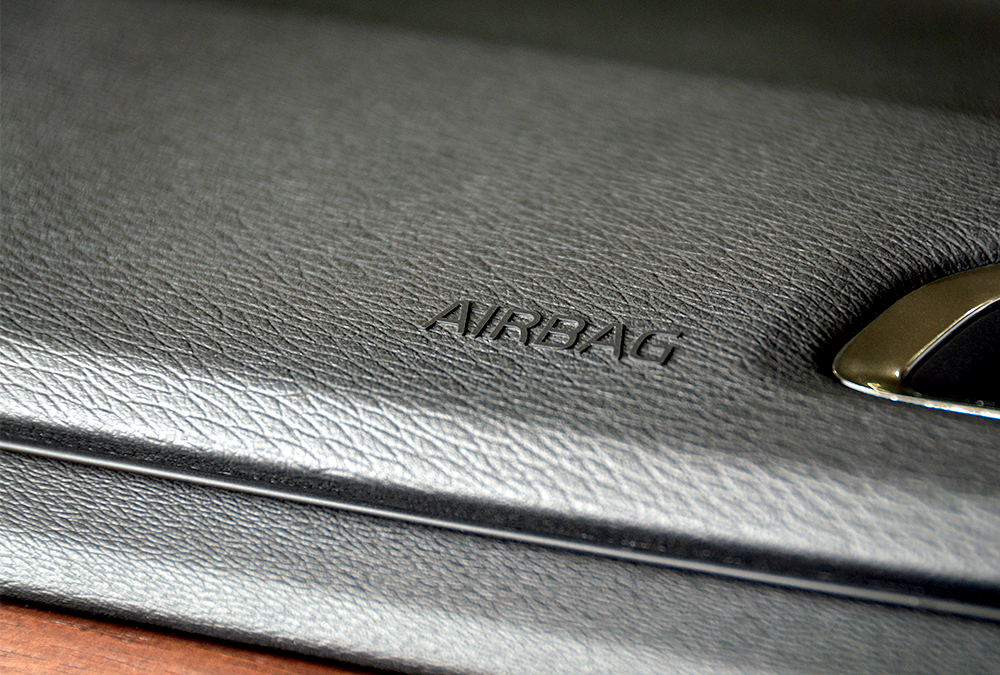

The various characteristics of IDY yarns like HT (High Tenacity), HMLS (High Modulus Low Shrinkage), LS (Low Shrinkage) as well as SLS (Super Low Shrinkage) are mainly used in fabrics for the automotive industry, tirecord, airbags, seatbelts etc. But also in home textiles such as sun-blinds, marquees etc. and in nautic textiles as canvas, ropes etc. IDY filament yarns are most suitable.

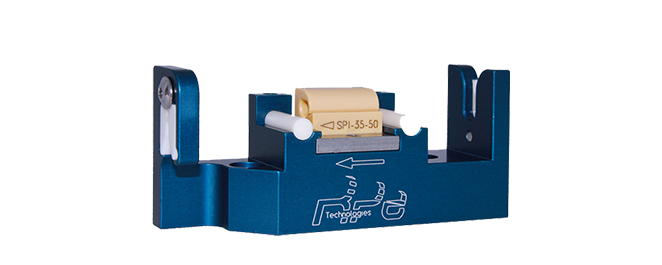

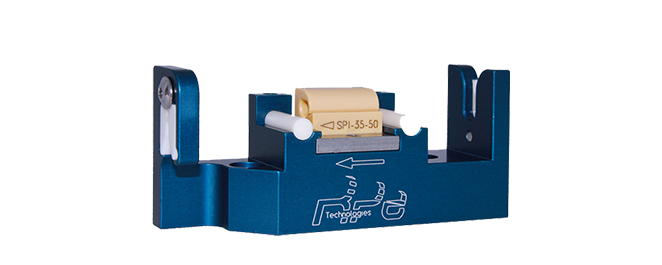

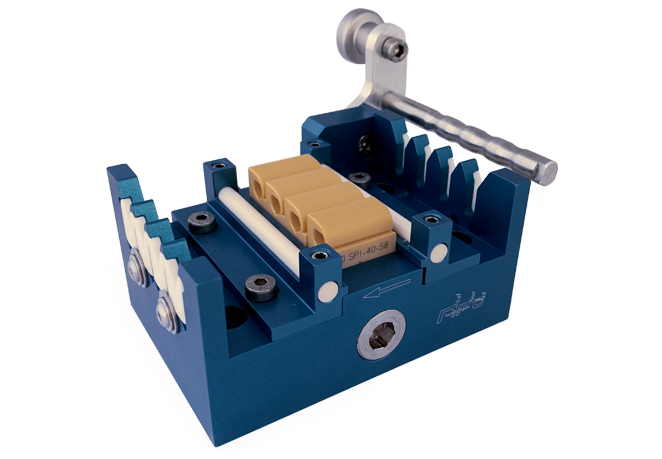

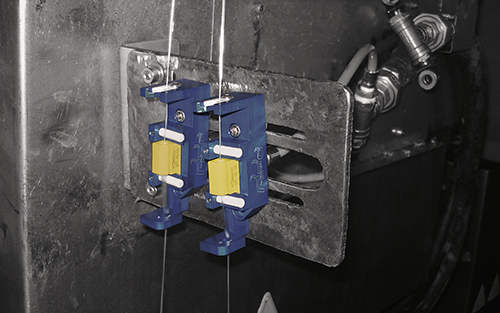

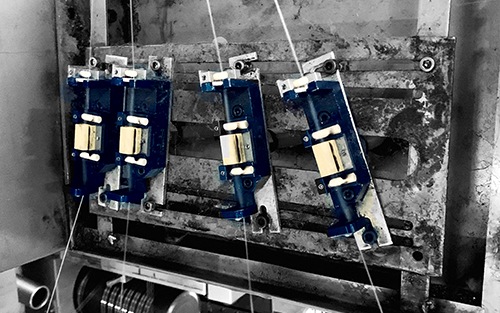

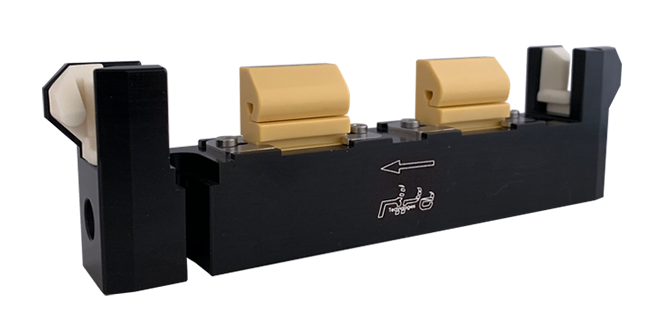

SPI interlacing jets

SPI jet, A-type

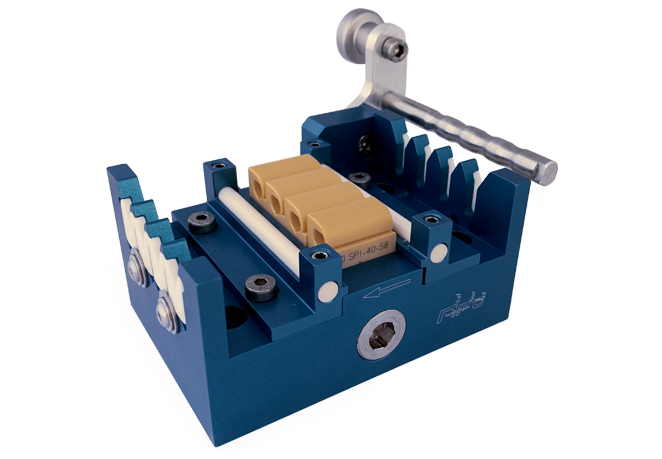

4-thread SPI jet

SPI technology

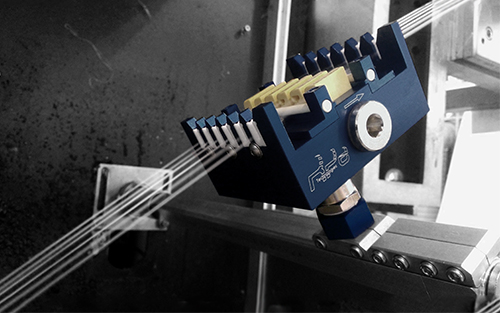

The SPI jet has been developed for high performance interlacing applications of IDY filament yarns made of polyester, polyamide as well as polypropylene.

The easy quick exchange system of the jet inserts allows a simple and safe maintenance.

The sophisticated geometry and surface character within the interlacing zone guarantee an excellent interlacing performance concerning the high requirement of the composed knot regularity.

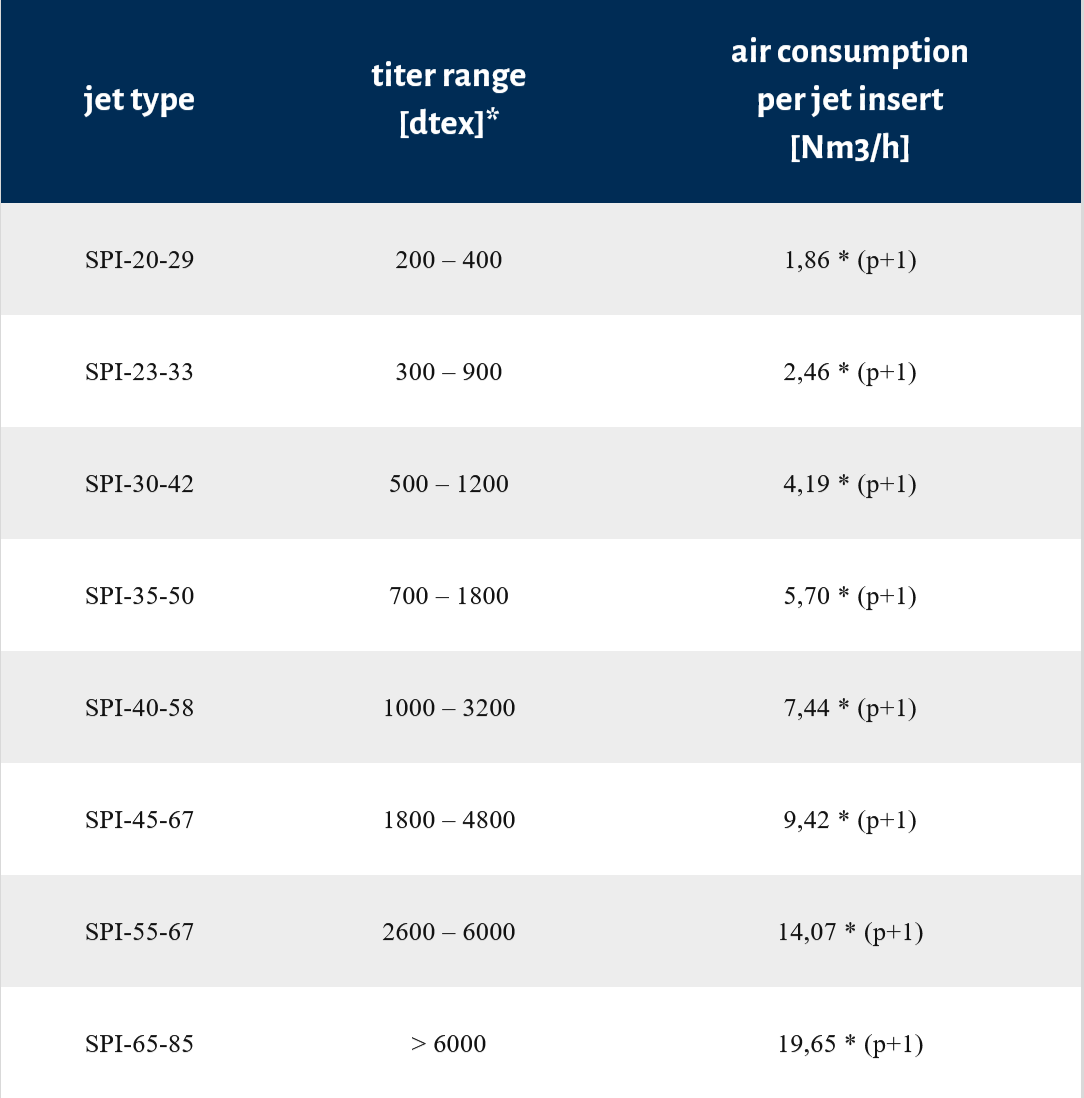

jet type | titer range [dtex]* | air consumption |

|---|---|---|

SPI-20-29 | 200 – 400 | 1,86 * (p+1) |

SPI-23-33 | 300 – 900 | 2,46 * (p+1) |

SPI-30-42 | 500 – 1200 | 4,19 * (p+1) |

SPI-35-50 | 700 – 1800 | 5,70 * (p+1) |

SPI-40-58 | 1000 – 3200 | 7,44 * (p+1) |

SPI-45-67 | 1800 – 4800 | 9,42 * (p+1) |

SPI-55-67 | 2600 – 6000 | 14,07 * (p+1) |

SPI-65-85 | > 6000 | 19,65 * (p+1) |

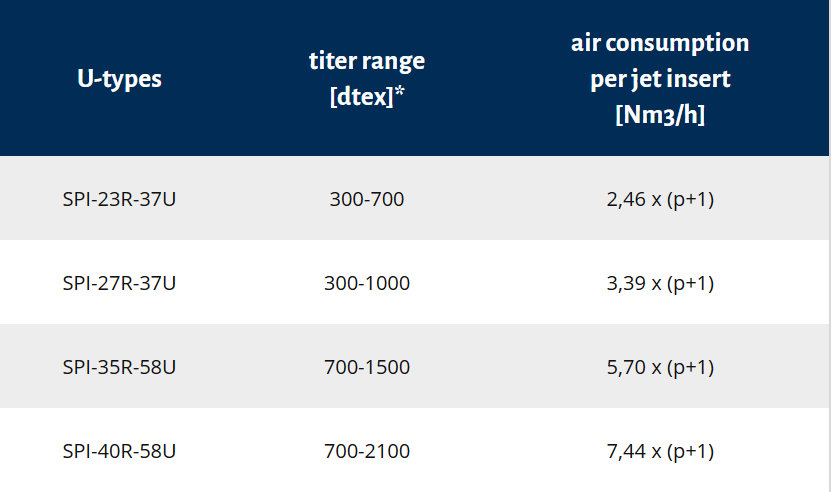

U-types | titer range

[dtex]* | air consumption

per jet insert

[Nm3/h] |

|---|---|---|

SPI-23R-37U | 300-700 | 2,46 x (p+1) |

SPI-27R-37U | 300-1000 | 3,39 x (p+1) |

SPI-35R-58U | 700-1500 | 5,70 x (p+1) |

SPI-40R-58U | 700-2100 | 7,44 x (p+1) |

Most important for the right choice of insert size is the specific required interlace performance.

SPI interlacing jets

SPI jet, A-type

4-thread SPI jet

SPI technology

The SPI jet has been developed for high performance interlacing applications of IDY filament yarns made of polyester, polyamide as well as polypropylene.

The easy quick exchange system of the jet inserts allows a simple and safe maintenance.

The sophisticated geometry and surface character within the interlacing zone guarantee an excellent interlacing performance concerning the high requirement of the composed knot regularity.

Most important for the right choice of insert size is the specific required interlace performance.

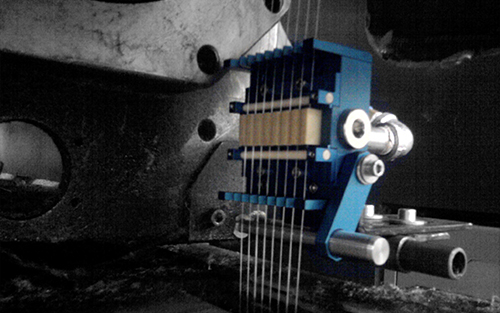

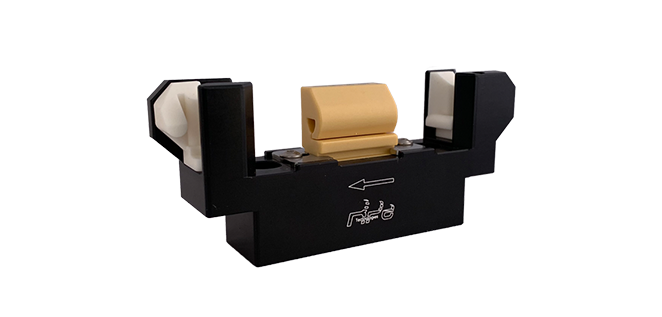

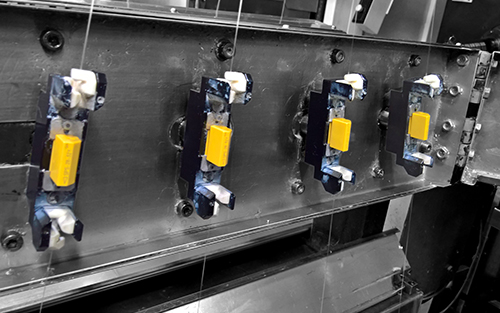

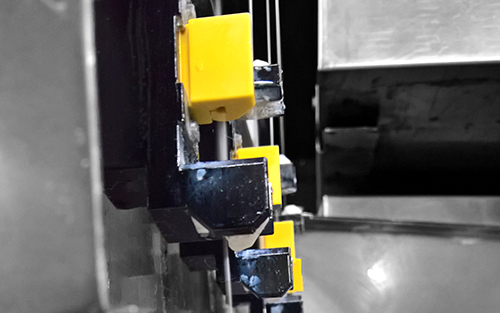

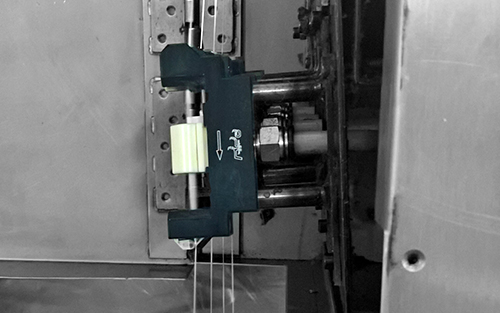

SPS interlacing jets

SPS jet

Due to the advanced geometry within the interlacing zone and the unique yarn guiding system, the SPS jet is most suitable for sensitive yarn applications such as SLS-, airbag- as well as seat belt yarns, especially concerning filament deteriorations.

jet type insert | titer range [dtex]* | air consumption per thread, single [Nm3/h] | air consumption per thread, tandem [Nm3/h] |

|---|---|---|---|

SPS-23-32Y | 300 – 800 | 2,46 * (p+1) | 4,92 * (p+1) |

SPS-28-32Y | 500 – 1200 | 3,65 * (p+1) | 7,30 * (p+1) |

SPS-35-48Y | 800 – 1800 | 5,70 * (p+1) | 11,40 * (p+1) |

SPS-40-48Y | 1000 – 3000 | 7,44 * (p+1) | 14,88 * (p+1) |

Most important for the right choice of insert size is the specific required interlace performance.

single SPS jet

tandem SPS jet

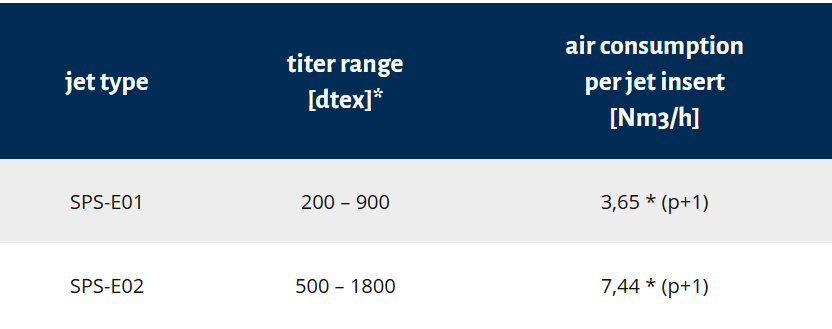

SPS jet, E-type

jet type | titer range [dtex]* | air consumption per jet insert [Nm3/h] |

|---|---|---|

SPS-E01 | 200 – 900 | 3,65 * (p+1) |

SPS-E02 | 500 – 1800 | 7,44 * (p+1) |

Most important for the right choice of insert size is the specific required interlace performance.

SPS jet, E-type

SPS interlacing jets

single SPS jet

tandem SPS jet

SPS jet, E-type

SPS jet

Due to the advanced geometry within the interlacing zone and the unique yarn guiding system, the SPS jet is most suitable for sensitive yarn applications such as SLS-, airbag- as well as seat belt yarns, especially concerning filament deteriorations.

Most important for the right choice of insert size is the specific required interlace performance.

SPS jet, E-type

Most important for the right choice of insert size is the specific required interlace performance.

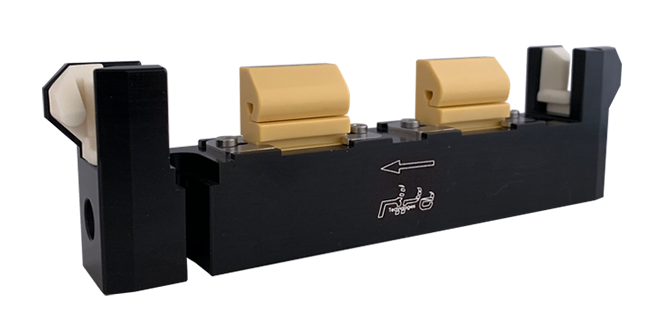

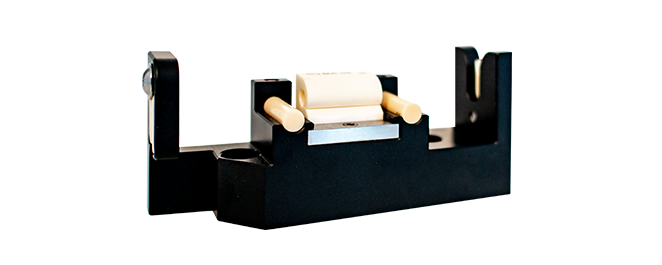

BMI migration jets

BMI migration jet

The BMI jet geometry has been developed to ensure effective mixing of filaments while optimizing energy consumption.

Those nozzles are best suited for the migration of IDY yarns and can be used for all types of technical filament yarns.

The design allows the use of single as well as multiple-thread jets with filament pitches up to 5.5mm in any conceivable filament count and arrangement.

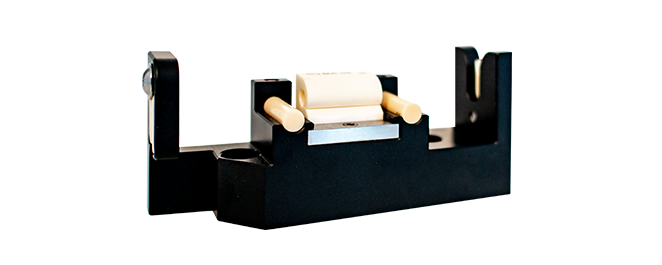

jet type | titer range [dtex]* | air consumption

per jet insert

[Nm3/h] |

|---|---|---|

BMI-02 | 200-1200 | 2,01 x (p+1) |

BMI-03 | 500-2000 | 2,65 x (p+1) |

BMI-04 | 1000-3000 | 3,22 x (p+1) |

Most important for the right choice of insert size is the specific required interlace performance.

BMI migration jets

BMI migration jet

The BMI jet geometry has been developed to ensure effective mixing of filaments while optimizing energy consumption.

Those nozzles are best suited for the migration of IDY yarns and can be used for all types of technical filament yarns.

The design allows the use of single as well as multiple-thread jets with filament pitches up to 5.5mm in any conceivable filament count and arrangement.

Most important for the right choice of insert size is the specific required interlace performance.

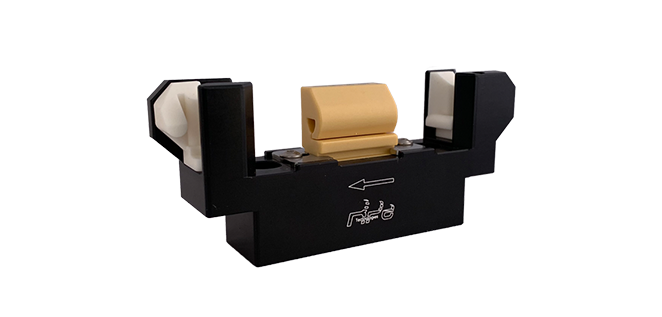

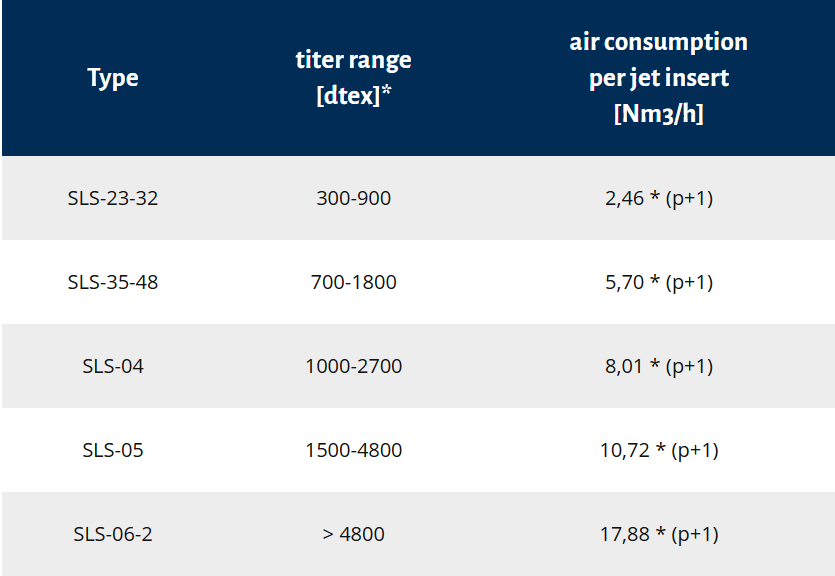

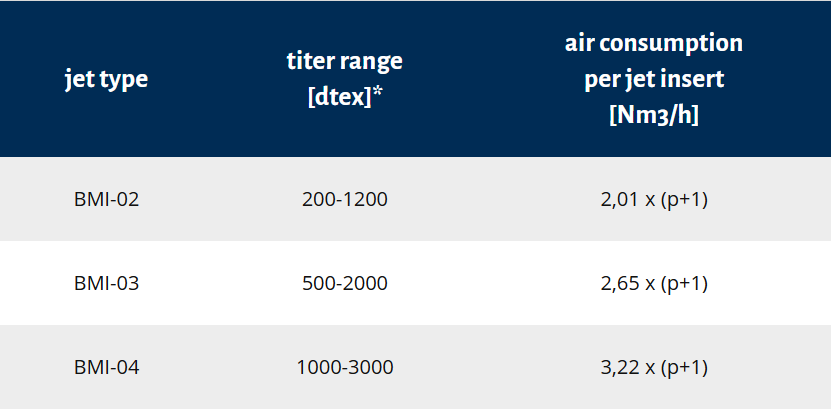

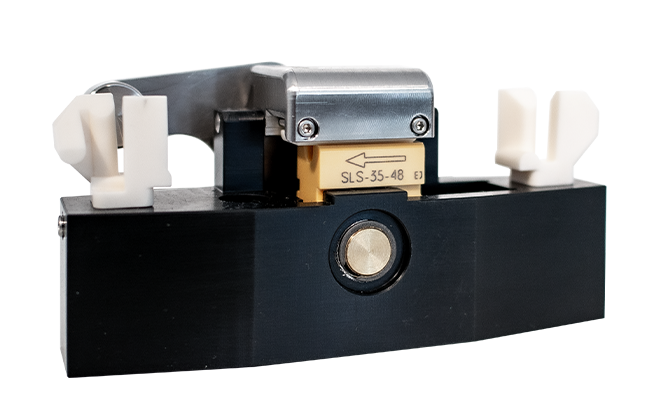

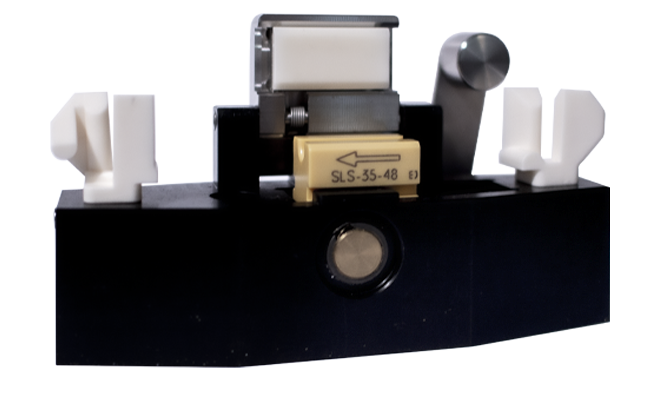

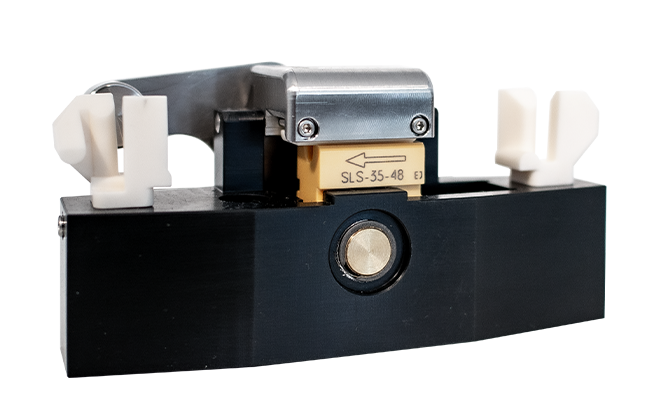

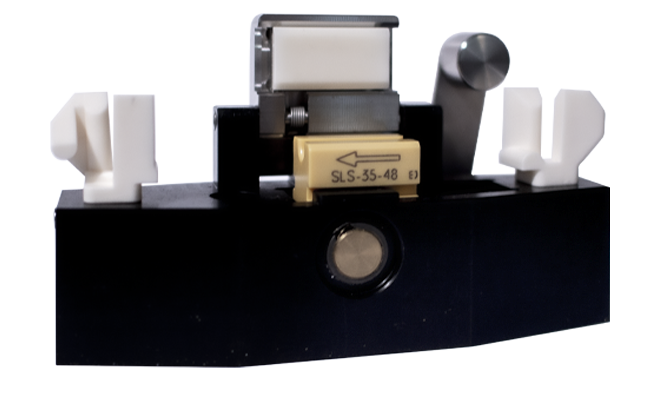

SLS interlacing jet

The SLS interlacing jet is a single-thread opern/closed - design that has been developed to interlace fibers that are difficult to intermingle. The jet can be used directly in the spinning process, but is also well suited for use in winding machines.

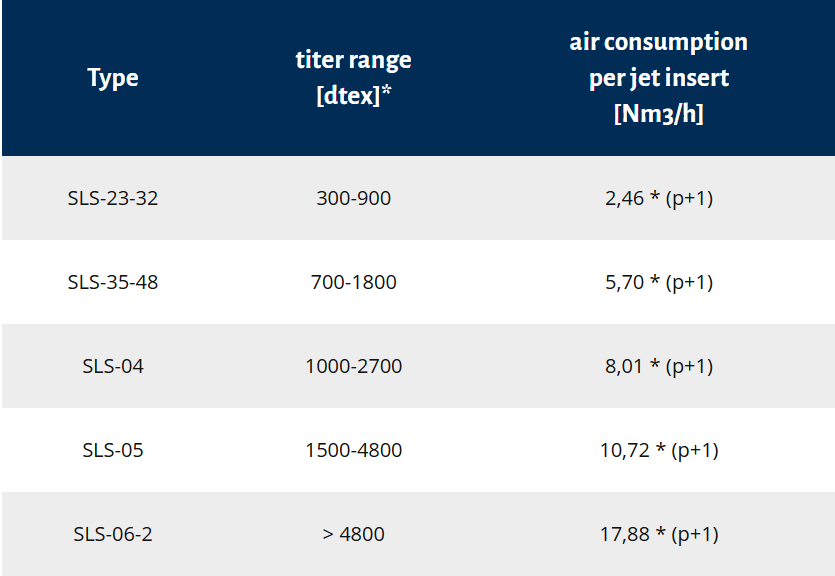

Type | titer range [dtex]* | air consumption

per jet insert

[Nm3/h] |

|---|---|---|

SLS-23-32 | 300-900 | 2,46 * (p+1) |

SLS-35-48 | 700-1800 | 5,70 * (p+1) |

SLS-04 | 1000-2700 | 8,01 * (p+1) |

SLS-05 | 1500-4800 | 10,72 * (p+1) |

SLS-06-2 | > 4800 | 17,88 * (p+1) |

Most important for the right choice of insert size is the specific required interlace performance.

SLS jet closed

SLS jet open

SLS interlacing jet

SLS jet closed

SLS jet open

The SLS interlacing jet is a single-thread opern/closed - design that has been developed to interlace fibers that are difficult to intermingle. The jet can be used directly in the spinning process, but is also well suited for use in winding machines.

Most important for the right choice of insert size is the specific required interlace performance.